Viscosity expresses the inner friction and the fluidity of the lubricant. It describes the hydrodynamic lubricity.

- Usually given as kinematic viscosity η at +40 °C

- Unit mm2/s (old: cSt)

- Accord. ASTM D7042, ASTM D445, DIN 51562, DIN 51659

- Conversion by the density ρ into the dynamic viscosity η possible v = η / ρ

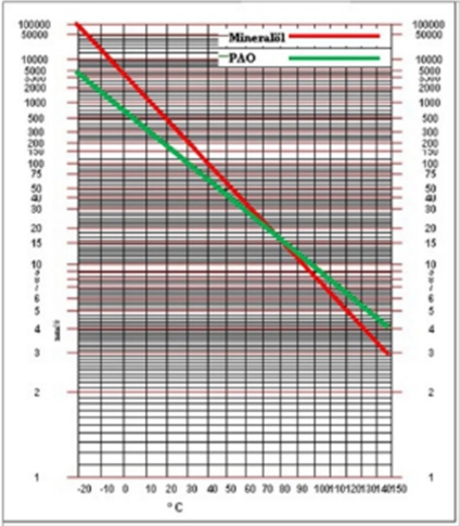

- Depending on the temperature (see VT diagram) and pressure (only relevant above 500 bar)

Simplified selection criteria for the viscosity for an application:

- At high pressure → chose a higher viscosity

- At high rotational speed → chose a low viscosity

Impacts of a wrongly chosen viscosity:

To low

- Lubricating film is too thin

- Enhanced wear and reduced lifetime

To high

- Lubricant is unsuited for the conveying system and does not reach the lubrication points

- Deficient lubrication and wear

- Enhanced inner friction with increased energy consumption

The viscosity index is given by the temperature-viscosity relation (VT behaviour)

- No unit

- Determination acc. to DIN ISO 2909

- Allows calculation of kinematic viscosity at various temperatures

- Higher VI values are of advantage since temperature changes do not result in large viscosity changes i.e. less viscosity change at a varying temperature → Oil covers larger temperature range.

The density is the ration from mass to volume

ρ = m/V

- Unit g/cm3

- Crucial for the conversion of dynamic and kinematic viscosity

- Allows conversion of mass m to volume V and vice versa